Proudly Introducing 3-station Thermoforming Machine

Unveil a new era of packaging excellence with our state-of-the-art thermoforming machine designed for the production of packaging products in ®PET, PP, PS, OPS, PLA, PE, and other cutting-edge materials.

Leveraging three decades of hardcore expertise in mould-making, our commitment to innovation is mirrored in every component. We integrate internationally renowned brands to ensure a higher degree of performance, reliability, and efficiency.

Technical Data

Technical Data | FCS 6655 |

Maximum Forming Area | 665mm x 540mm |

Maximum Forming Height | 100mm |

Air Pressure | 6 Bar |

Sheet Thickness | 0.25 – 1.5mm |

Suitable Material | PP, PET, HiPS, OPS, PVC |

Clamping Force | 50MT |

Cutting Force | 50MT |

Maximum Cycle Speed | 40 cpm |

Machine Weight | 8000 kgs |

Our Machine Vs Others

Cost-effective Production

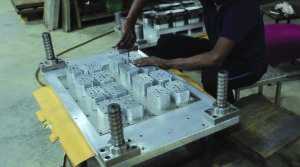

Durable Mould Materials

Consistent Quality

Less Energy Consumption

Advanced Thermoforming Innovations

upper table

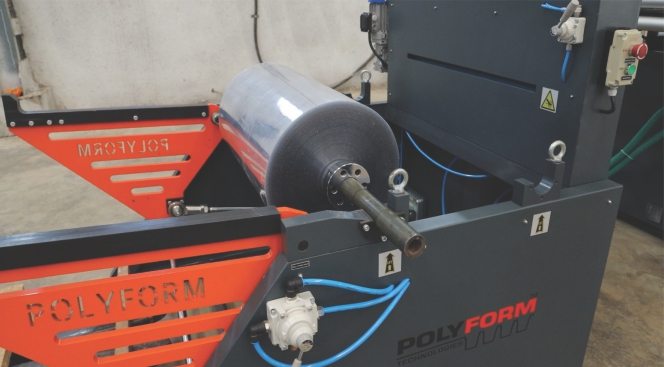

Unwinder

Experience seamless production with our thermoforming machine’s robust loading system featuring an auto unwinder. Effortlessly feed materials into the machine, enhancing efficiency and ensuring a continuous workflow.

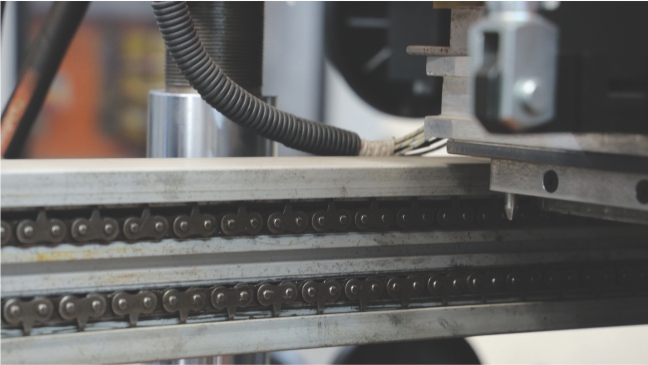

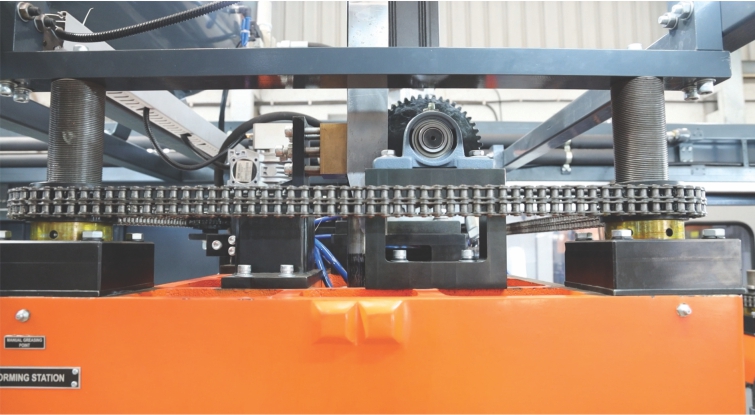

Frictionless Chain Transport

This cutting-edge feature ensures smooth material transportation, minimising friction for impeccable control. Experience a new level of accuracy and reliability as your materials move seamlessly through the production process.

Heating

Optimize your thermoforming process with the superior heating capabilities of our machine, utilizing European efficient ceramic elements. Experience precision and energy efficiency as these high-quality components ensure uniform and controlled heating, allowing you to achieve the perfect temperature for a wide range of materials

Interface with Touch Screen

Simplify your operational experience with our thermoforming machine’s user-friendly interface, featuring a visual touchscreen. Seamlessly navigate through settings and controls with ease, ensuring an intuitive and straightforward operation. Enhance efficiency and user engagement with a simple yet sophisticated interface that puts precision at your fingertips

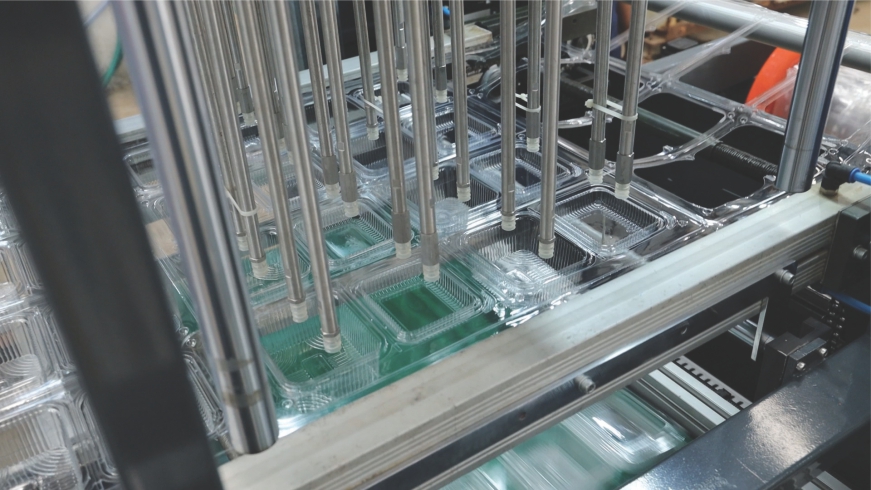

Forming & Cutting Station

Experience unparalleled durability and precision with our thermoforming machine forming and cutting station, housed in a solid steel cast structure. The integration of needle bearings for toggle mechanisms ensures smooth and reliable performance, delivering precise forming and cutting for your manufacturing needs. Trust in the robust construction of our machine to elevate the quality and longevity of your production processes.

Higher Clamping & Cutting Force

Experience elevated productivity as the higher clamping force secures materials with precision, while increased cutting force ensures accurate and efficient shaping. Maximize your manufacturing capabilities with the superior force dynamics of our machine, delivering unmatched efficiency in every operation.

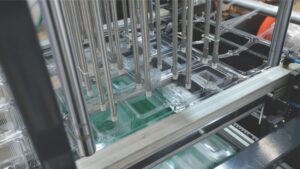

Downward / Upward Stacking

Adapt to diverse packaging needs effortlessly with our thermoforming machine’s flexible stacking options, offering both downward and upward stacking capabilities. This versatile feature allows you to customize your production process, providing the flexibility to meet specific requirements.

upper table

Independent servo-plug drive on upper table

This innovative feature ensures autonomous control, allowing for fine-tuned adjustments and accuracy during the moulding process. Experience unparalleled flexibility and responsiveness, as the independent servo-plug drive enhances your capability to achieve intricate and tailored results in each production cycle.

Electronic Control Panel

Navigate through settings with ease and precision, ensuring optimal operational control. Experience the efficiency of a streamlined production process as our electronic control panel empowers you with intuitive and accurate command over every aspect of your thermoforming operations.

Gallery